Welcome to Shenzhen Isew Thread Co., Ltd!

Selecting Your Sewing Threads

Introduction

The smallest failure in thread performance results in losses on investments in material, equipment, garment engineering, and labour. Hence, it is important to know your thread thoroughly. Enhancing thread knowledge, analysing thread parameters, the right selection procedure and use of thread plays a major role in achieving good sewing performance and the desired seam quality.

This Bulletin Post serves an introduction to the types of threads, the properties, thread construction, and factors affecting thread performance.

What is a sewing thread?

Sewing threads are special kinds of yarns that are engineered and designed to pass through a sewing machine rapidly. They form efficient stitches without breaking or becoming distorted during the useful life of the product. The basic function of a thread is to deliver aesthetics and performance in stitches and seams.

What are the factors that affect functions of a sewing thread?

Factors affecting aesthetics

Colour, lustre and fineness / thickness should be considered while selecting a thread for decorative purposes such as top stitching or embroidery.

- Hue and shade matching

- Colour fastness

- Stitch selection

- Uniformity of stitch formation

Factors affecting performance

Thread used in garments must be durable enough to withstand the abrasion and needle heat that occur while sewing, garment finishing, stretching and recovery during wear.

Thread performance in garments can be evaluated from its:

- Seam strength

- Abrasion resistance

- Elasticity

- Chemical resistance

- Flammability

- Colour fastness

What is 'sewability'?

'Sewability' of thread is a term used to describe a sewing thread’s performance. A thread with good sewability is uniform in diameter with a good surface finish. Longitudinal uniformity of thread contributes to uniform strength and reduced friction, as it passes through the stitch forming mechanisms. It also minimises thread breakages and the associated costs incurred from rethreading machines, repairing stitches and producing inferior quality products.

Sewability parameters

The parameters that define the superior sewability of thread are:

- No breakages in high-speed sewing

- Consistent stitch formation

- No skipped stitches

- Evenness, to prevent changes in tension during sewing

- A high level of abrasion resistance

- Sufficient surface smoothness, to pass easily through the machine guides

Thread classification

Thread can be classified in different ways. Some common classifications are those based on:

- Substrate

- Construction

- Finish

1. Classification based on substrate

Natural

The usage of thread made from natural substrates is now minimal in industry applications. However, the most commonly used natural thread is cotton thread.

Synthetic

Due to the limitations of natural fibres, thread users have turned to threads made from synthetic fibres as they have desirable properties of exceptionally high tenacity, high resistance to abrasion and good resistance to chemicals. They are also not significantly affected by moisture, rot, mildew, insects or bacteria.

2. Classification based on construction thread structure

Spun Thread is made using natural or synthetic fibres. Spun polyester is one of the most widely used threads. It is stronger than cotton threads of a comparable size, and is available in a wide variety of sizes and colours.

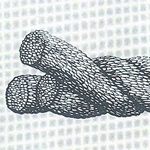

Corespun Thread is a combination of staple fibres and filaments. The most commonly used corespun thread has multiple-ply construction, with each ply consisting of a polyester filament core with cotton or polyester fibres wrapped around the core.

This thread structure influences the strength of filament polyester and the sewability of cotton or polyester fibre wrap. Corespun thread is generally used for the high-speed sewing of many garment types, especially those requiring high seam strength.

Filament threads are stronger than spun threads of the same fibre and size.

Three types of filament threads are commonly used:

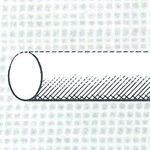

Monofilament Thread is made from a single continuous fibre with a specified thickness. Though monofilament is strong, uniform and inexpensive to make, it lacks flexibility and is stiff and scratchy in feel. As a result, usage is normally restricted to hems, draperies, and upholstered furniture.

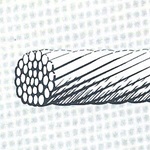

Smooth Multifilament Thread is usually made from nylon or polyester and is used where high strength is a primary requirement. It consists of two or more continuous filaments twisted together. It is commonly used to sew shoes, leather garments, and industrial products.

Textured Filament Thread is usually made from polyester and is used primarily as the looper thread for cover stitches. Texturing filaments gives the yarn more cover and high extensibility, but makes the thread more subject to snagging.

Basics of thread construction

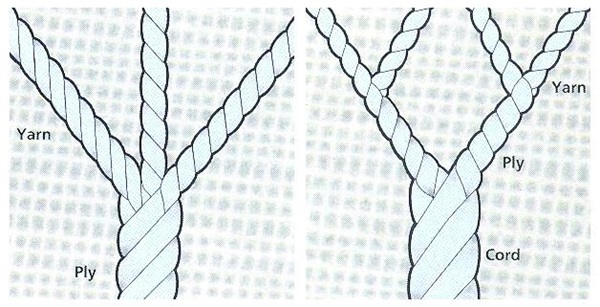

All conventional sewing threads begin their production cycle as simple yarns. These basic yarns are produced by twisting together relatively short fibres or fine continuous filaments.

Some terms used in the context of thread construction are:

Twist – Twist is simply the number of turns per unit length. A thread with too little twist may fray and break, one with too much twist can cause snarling, looping and knotting. Balance is the key and a good sewing thread has it.

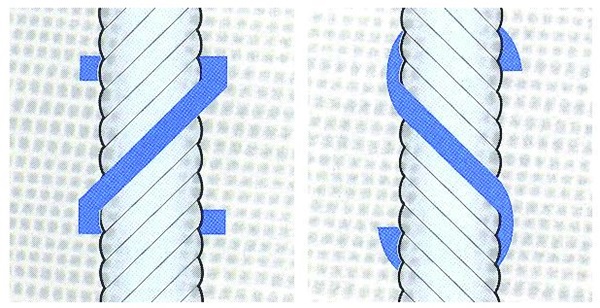

Twist direction – The direction of the finishing twist is important, twist can be inserted in either direction and this is described as either Z or S twist. Most common machines use a Z twist thread. There are other descriptions of twist which were used in the past but these should not be used to avoid confusion.

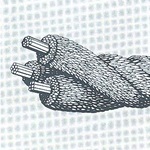

Ply and cord – Yarns with many components are twisted together to form ply thread. Most commonly used are 2, 3 or 4 ply threads. Threads are twisted together to give corded thread. Most commonly used are 4, 6 or 9 cord threads.

Size – The overall thickness of the final thread is referred to as ‘Grist’, ‘Ticket Number’, ‘Tex’ or ‘Count’. Thread should be as fine as possible depending on the required strength of seam. Generally, thicker threads have greater strength, given the same fibre content and yarn structure. Finer threads tend to blend into the fabric surface and are less subject to abrasion than seams with heavier threads. Finer threads perform better with finer needles and produce less fabric distortion than heavier needles.

3. Classification based on thread finish

Finishes are given to a thread for two purposes

1. To improve sewability

Some finishes involve increasing strength, abrasion resistance and lubrication of the thread.

2. To achieve a specific functional requirement

Some finishes include bonding, non wick, anti-fungal, fire retardant, water repellent and anti-static finishes.

Package support

Sewing threads are put in different types of packages according to the types of thread, machines and sewing needs. Package support is important for the thread to perform at its best during transport and usage in machines. Packages may be colour coded according to the size and type of thread for easy identification.

Thread terminology

With a wide selection of threads to choose from, it is important to know some of the terminology associated with significant thread properties to judge the differences between different thread types.

Tensile strength is the tension at which a thread breaks, expressed in grams or kilograms (force).

Tenacity is the relative strength obtained by dividing the tensile strength by the thickness of the structure.

Loop strength is the load required to break a length of thread which is looped through another length of the same thread.

Minimum loop strength is the strength of the weakest loop in a series of loops (tested in a continuous length of thread).

Elongation at break is the amount by which a thread is extended at its breaking point expressed as a percentage of its original length.

Modulus is a term used to denote a numerical value which indicates the manner in which the textile behaves when a tensile force is applied.

Elasticity is a property of the thread which enables it to recover to its original length after being extended by a set amount.

Shrinkage is the amount by which a thread contracts under the action of washing or heating.

Moisture regain is the weight of moisture in a fibre or thread expressed as a percentage of weight of completely dry material.

Requirements of good quality sewing thread

Good tensile strength holds the stitched seam securely during wash and wear.

Smooth surface and absence of faults ensures less friction between the needle and the material during high-speed sewing. The thread must be well lubricated to increase its sewability and resistance to abrasion.

Uniform thickness / diameter results in an even sewing thread, which moves smoothly and quickly through the needle eye and the fabric. It also affects the thread’s tensile strength, resistance to abrasion and its twist construction. An uneven thread may twist into short knots and jam at the eye of the needle.

Good elasticity enables thread to recover its original length immediately after the tension has been released. The elasticity of sewing thread affects the strength and the finished quality of a stitched seam.

Good colour fastness provides immunity to the different agents the thread is exposed to during manufacture and washing. The thread must hence be uniformly dyed.

Low shrinkage of the thread being used on the fabric material with higher shrinkage reduces the chances of seam puckering.

Good resistance to chemical attack is a desirable property for thread used in garments which may undergo washing, bleaching or dry-cleaning.

Good abrasion resistance ensures a good sewing performance and makes the thread more durable.

The following figures show the results of thread-to-thread abrasion tests and give an indication of their respective resistance to abrasion:

If Linen, Rayon Continuous Filament (CF) has resistance of 1, then:

- Cotton = 3

- Spun Silk = 4

- Spun Polyester = 12

- CF Polyester = 30

- Spun Nylon = 40

- CF Nylon = 150

Good colour fastness will retain the thread’s original colour without running or fading when subjected to wash and light exposure. The thread colour should be resistant to different agents to which it is exposed during manufacture and use.

Colour fastness can be measured against:

- Chlorinated water

- Perspiration

- Cold water staining

- Dry cleaning

- Pressing - wet and dry

- Bleaching

Minimal metamerism can be achieved by assessing colour with colour matching cabinets. Metamerism is an inherent property of a thread when the same thread colour appears to be different under different lighting conditions. Standard illuminants are often used to counter the effects of metamerism.

- Share:

- Back to News List